For Weighbridge Software Free Demo

Upcoming ENGIMACH Exhibition | Codeshilp Global Solutions Pvt. Ltd. | 3,4,5,6,7 December 2025 | Dome :- 11 Stall :- 101 | Address :- Helipad Exhibition Centre, Gandhinagar.

Inquiry Now

Your message has been successfully sent. Thank you!

A weighbridge is used to measure the weight of vehicles for industrial, commercial, or logistics applications. Traditional weighbridges often involve manual operation, leading to errors and time delays. Automating the process using a Programmable Logic Controller (PLC) ensures accuracy, efficiency, and data integration.

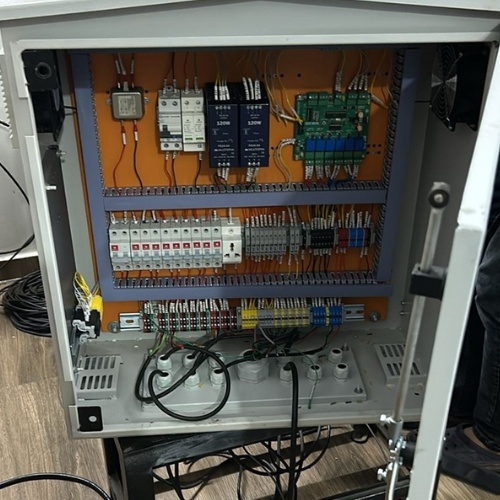

Components Used

- Load Cells: Convert mechanical weight into electrical signals.

- Signal Conditioner / Transmitter: Amplifies and converts load cell signals to 4–20 mA or 0–10 V for PLC input.

- PLC (e.g., Siemens, Allen-Bradley, Delta): Controls logic operations.

- HMI (Human Machine Interface): Displays real-time weight and system status.

- Weighbridge Platform: Mechanical structure for vehicle loading.

- Computer Interface (optional): For data logging and ticket generation.

PLC Controller

- Type : Wall/Floor Mounted Metal Enclosure

- Material : CRCA Sheet Steel, 14/16 gauge

- Finish : Powder Coated (RAL 7035 or as specified)

- Ingress Protection : IP54

- Cable Entry : Bottom/Side with cable glands

- Mounting : Wall/Surface Mount with brackets or screws

- Door : Hinged, with lockable latch and rubber gasket for sealing

- SPD (Surge Protection Device) : Class II, 275V AC, 20kA minimum per phase, with indication

- MCB (Miniature Circuit Breaker) : ISI marked, 6A–32A, 10kA breaking capacity, individual MCB for each load

- RCBO (Residual Current Breaker with Overload) : 30mA sensitivity, 2P, 6–32A rating, ISI certified

- EMI Filter : 250V AC, minimum 10A, two-stage, metal enclosure

- SP (Switching Point) for Each Device : Modular ON/OFF switches with labels

- Input Voltage : 230V ±10%, 50Hz AC

- Max Load Capacity : 2 kW (customizable based on devices)

- Isolation : Provided via MCB/RCBO

- Earth Terminal : Brass strip with minimum 10 connections

- Control Interface : Ethernet (RJ45) / RS232

- Output Channels : 6 Relay Outputs (NO/NC contacts)

- Relay Rating : 10A @ 250V AC / 30V DC

- Input Channels : 6 Digital Sensor Inputs

- Supported Devices : Boom Barrier, Traffic Light, RFID, Alarm, Gate Motor, ANPR, Human Detection etc.

- Sensor Types : Vehicle Detector, IR Beam, Limit Switch, etc.

- Control Logic : Programmable via Web Interface / Modbus / Serial Commands

- Power Supply : 12V or 24V DC (as per model)

- Operating Voltage Range : 9V–28V DC

- Indicators : LED indicators for Power, Inputs, Outputs, and Communication

- Connectivity : Modbus TCP/IP, Serial Command Set (RS232)

Working Principle

- The vehicle moves onto the weighbridge platform.

- Load cells detect the force and generate millivolt signals proportional to the load.

- The signal conditioner converts this to a PLC-readable analog signal.

- The PLC continuously monitors the input, processes calibration factors, and calculates total weight.

- Weight is displayed on the HMI and optionally sent to a database or printed slip.

- Logic controls barriers, traffic lights, or RFID systems for automatic entry/exit.

Objective

- Automate vehicle weighing using PLC control.

- Reduce human error and processing time.

- Interface weighbridge data with digital display and computer systems.

- Enable data storage and remote monitoring.

An authorized Service Provider of Software such as Customized Weighbridge Management System, Petrol Pump Software, Tally Software of Different Platforms, Petty Cash Management System, Salt Factory Management System and CRM Software. Our experienced team work on the basis of actual customer requirement and do some customization if require. Our Company, We pride ourselves on our commitment to excellence, attention to detail, and Customer Satisfaction.

GSTINO : 24AAMCC3287E1ZN

MSME No : UDYAM-GJ-01-0497074

An authorized Service Provider of Software such as Customized Weighbridge Management System, Petrol Pump Software, Tally Software of Different Platforms, Petty Cash Management System, Salt Factory Management System and CRM Software. Our experienced team work on the basis of actual customer requirement and do some customization if require. Our Company, We pride ourselves on our commitment to excellence, attention to detail, and Customer Satisfaction.

© 2025 All Rights Reserved.